Copy settings from Simply MODBUS RTU Master to our Modbus Data Logger

Problem scenario:

I can successfully test and read data from my MODBUS RTU device using the Simply MODBUS RTU Master software. How can I copy a MODBUS query settings to your logger because I would like to monitor my device for a long time?

Requirements:

- Data Logger Suite Professional, Enterprise, or a trial version.

It is assumed that:

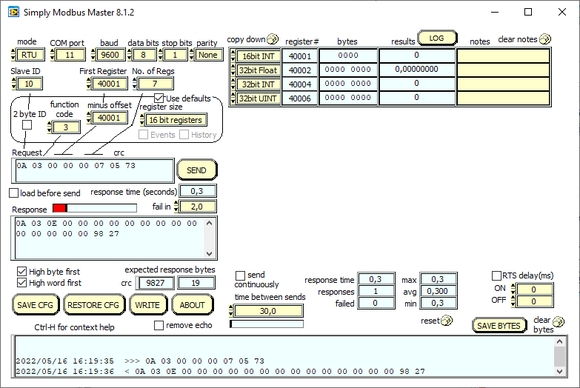

You can successfully read data from your MODBUS device using Simply MODBUS (fig. 1).

Fig. 1: Simply MODBUS RTU query settings.

Solution:

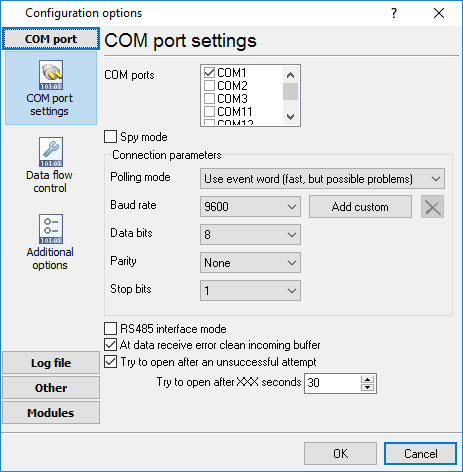

1. Create a new configuration from the main window using the "Green Plus" button. (fig. 2). This example shows the connection settings for MODBUS RTU. If your device uses MODBUS TCP, look here. Copy all communication parameters from Simply MODBUS:

- COM port → COM ports.

- Baud → Baud rate.

- Data bits → Data bits.

- Stop bits → Stop bits.

- Parity → Parity.

- Spy mode - disable this option.

- RS485 mode - enable this option, if you connected your MODBUS are on an RS-485 bus, and you use RS485-USB or RS485-RS232 converter.

- Other options - leave the default value as shown below.

Fig. 2: Configuring RS232 MODBUS RTU connection.

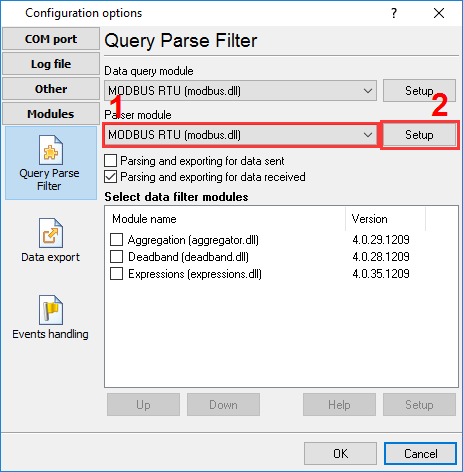

2. Activate the "MODBUS RTU" plugin in the settings in both fields "Data query module" and "Parser module" (fig. 3). Please do not confuse it with "MODBUS RTU [Passive]" or "MODBUS RTU [Slave]" because they realize other functionality. We configure the MODBUS master station. Note: If your settings "Register size" is "32 bit registers", you should select the "MODBUS RTU [Enron]" in both fields.

Fig. 3: Activating the MODBUS RTU plugin.

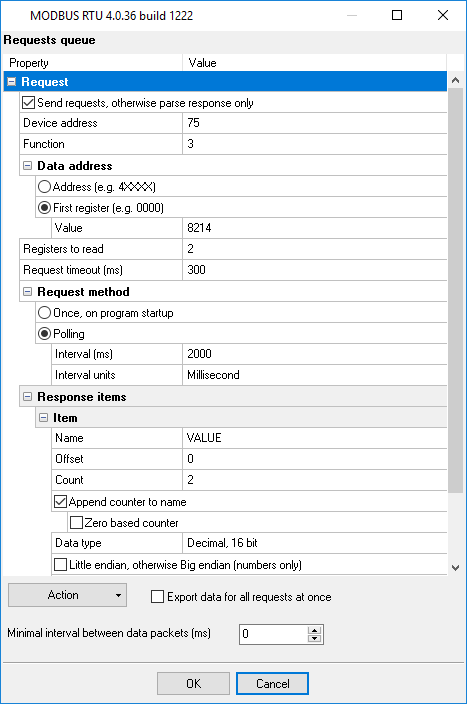

3. In the MODBUS RTU plugin settings, click the "Action → Add new request" button to add a new query request (fig. 4). Copy basic request settings from Simply MODBUS:

- Slave ID → Device address.

- Function code → Function.

- The result of the expression (First register - Minus offset) → First register - Value.

- Number of registers → Registers to read.

- The result of the expression (Response time * 2 * 1000) → Request timeout (ms).

- Polling - configure it as you want.

Fig. 4: Basic MODBUS query settings.

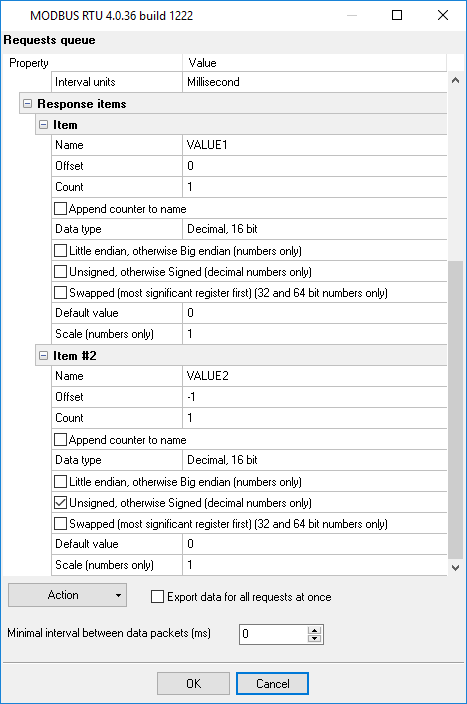

4. Add the necessary number of response items by clicking the "Action → Add response item" button:

- Name - any name of this value.

- Offset - it is the byte offset in response data without a device address, function code and data size. Set this value to "-1", and the program will calculate an offset automatically.

- Count - the number of sequential values with the identical data type and name.

- Append counter - it is used when "Count" is greater than 1.

- Data type - copy the type from the first column with response data items.

- Unsigned - enable this option if a data type in Simply MODBUS is an unsigned decimal (UINT) and disable in another case (INT).

- Little-endian - it has an inverted state of the "High byte first" option in Simply MODBUS.

- Swapped - it is the same as "High word first".

Note: The figure below is an example. It does not match response items on fig. 1. The full correct list of response items will look like:

- Name: VALUE1, Offset: -1, Count: 1, Data type: Decimal 16 bit, Unsigned: Off, Little-endian: Off.

- Name: VALUE2, Offset: -1, Count: 1, Data type: Float, Unsigned: Off, Little-endian: Off, Swapped: On.

- Name: VALUE3, Offset: -1, Count: 1, Data type: Decimal 32 bit, Unsigned: Off, Little-endian: Off, Swapped: On.

- Name: VALUE4, Offset: -1, Count: 1, Data type: Decimal 32 bit, Unsigned: On, Little-endian: Off, Swapped: On.

Fig. 5: MODBUS response items.

FAQ

How can I poll multiple MODBUS RTU devices?

MODBUS RTU allows you to connect up to 254 devices on one RS-485 bus. You may specify several addresses like 1,2,3,4,5 in the "Device address" field (fig. 4).

Can I poll MODBUS TCP devices?

Yes, of course. The settings are almost identical. You should configure the TCP connection settings and select other parser type (MODBUS TCP instead of MODBUS RTU) (fig. 3).

Related articles: Copy settings from Simply MODBUS RTU Master to our Modbus Data Logger

MODBUS RTU, MODBUS ASCII, MODBUS/TCP

- MODBUS power meter data logging (easy method)

- Sunspec-compatible MODBUS power meters, inverters (easy method)

- MODBUS RTU/TCP polling: Configuring master station Tags: MODBUS RTU, MODBUS TCP, requests, response items.

- MODBUS poll: How to make sure that the application sends requests and receives responses?

- MODBUS poll: How to view register values, not raw MODBUS packets?

- MODBUS polling: How to make sure that the application correctly interprets the responses received from the device?

- MODBUS polling: How to view MODBUS register values in a more easy-to-grasp form (graphs, indicators, etc.)?

- MODBUS: How to combine the data of two requests?

- MODBUS: What is the right way to poll multiple devices?

- Copy settings from Simply MODBUS RTU Master to our Modbus Data Logger.

- Copy settings from the MODBUS Poll utility.

- Controlling PLC coil registers status using MODBUS TCP Tags: MODBUS data parser, custom scripts, events generating, and handling.

- MODBUS to MSSQL: Write MODBUS registers to separate columns

- MODBUS to MySQL: Write MODBUS values to the MySQL database

- MODBUS to a database: Writing MODBUS RTU/TCP values to a database

- MODBUS to a database: Write data to two different tables.

- MODBUS to a database: Write data to two different databases, making a complete copy.

- Sentron PAC 3200: MODBUS TCP Data Logging

- Write data to a MODBUS device

- SQL to MODBUS: Send data from a SQL database to MODBUS.

- MODBUS TCP ↔ MODBUS RTU real-time conversion.

BACNET/IP

IEC 62056-21

- IEC 62056-21 power meter data logging Tags: Iskra Emco, Satec, Landis+Gyr.